Gimbal Project

Back in May 2009 I had spent some time tossing ideas back and forth with a nice gent by the name of Jentron on the #flightgear IRC channel (irc.flightgear.org). We were discussing the various methods that could be used to create a very inexpensive gimbal assembly for pitch & roll control in a home built flight simulator cockpit.

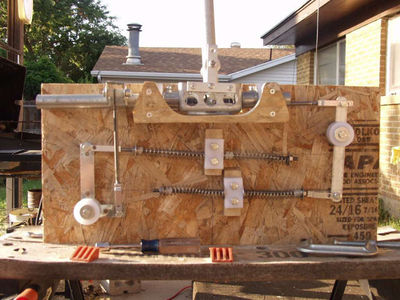

This is what Jentron developed:

As you can see, it's very simple and uses easily obtainable off the shelf hardware. In fact, this particular example was built entirely from the resources of his local Ace Hardware.

I've named his original gimbal design the "Mark I" to differentiate it from the design I'm using - but they're both built from essentially the same components.

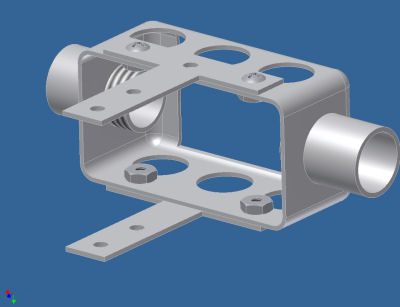

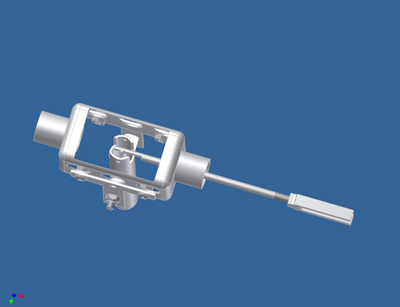

Here is what I call the Jentron Gimbal, Mk II:

As you can see, the design elements from the Mk I design are present here with a couple notable changes:

- The pitch axis bearings are two separate components.

- Simpler interconnect for the pitch axis centering arm - no need for a hand-fabricated pitch arm.

- Reduced part count

Jentron's design is perfectly usable in it's configuration, but I needed to modify it for use with the DIY Cockpit Project.

Besides, I'm a geek and no self respecting geek can resist fiddling with things. :)

Below is instructions on how you can construct this gimbal for use in your cockpit!

Building instructions

Here's information on how my version of the Jentron Gimbal Mk II was built and how you can build your own.

One important thing to note - the gimbal is designed to be mounted underneath the cockpit floor. This is what it looks like from above, in the "operating" position:

This article will only cover the ins and outs of the gimbal itself. The reason for this is that your application may be a bit different and you'll need to adjust other parts of the design to fit your situation.

Two "fancy" tools are going to be required to build this project.

- 1 Step Drill. This is used to enlarge the end holes in the single-gang extender box.

- 1/4" Die. This is used for threading the ends of the centering push-rods.

A cheap 1" Step Drill can be had for less than $30. In case you're not sure, a step drill looks like this:

Here's a list of some other common tools you're going to need:

- Hacksaw -or- a pipe cutter. Pipe cutters work better for cutting EMT.

- Drill

- Drill Bits - 1/4" and 13/64"

- Pop-Rivet gun

- Jig Saw, Band Saw or a Scroll Saw

- Two 7/16" open end wrenches

- 3/8" open end wrench

- Philips screwdriver

- Vice Grips (2 pair if you can)

- Vice or vice-like device

Materials needed to build the gimbal box:

- 1 each single-gang electrical extension box

- 2 each 3/4" EMT connectors

- 2 each 3" "T" Brackets

- 4 each 3/16" Pop-Rivets

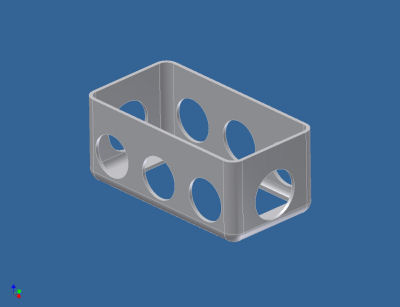

Now the first thing you're going to need to do is pop out all the knock-outs in the electrical box and then drill out the ends using the 1" Step Drill. The hole needs to be large enough to accept the threaded portion of the 3/4" EMT connector. When you're done, the box should look like this:

Next up, you're going to have to use your vice grips (2 pair if you have them!) to position the 3" "T" bracket on the side of the extension box. The best way to do this is to measure 1-1/2" in from the end of the "top" of the T brace and draw a centering line. Measure the electrical box along its long axis and mark the center of it. The centering lines ensure that you'll correctly position the "T" bracket on the side of the box.

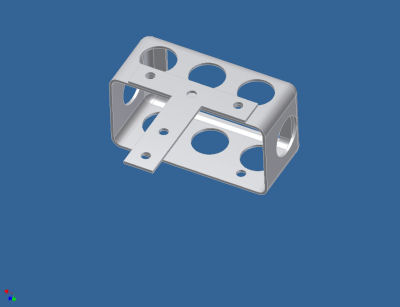

Position the box and T-Bracket like this:

With the vice grip(s) holding the t-bracket in place, put the box in a vice to hold it down. You're going to use a 1/4" drill bit to drill holes in the extension box, using the bracket as a guide. Do this for both brackets. When you've got all four holes drilled, go ahead and pop-rivet them in place - please be careful to make sure that both brackets are lined up with one another. The portion of the bracket that sticks out will be the support for the stick stub. It's got to be as close perfect as you can make it. In the end, you should have something that looks like this:

You'll notice in my drawing that I'm using screws to hold the brackets in. This was done because I didn't want to take the time to draw a reasonable looking pop rivet. :)

The last step is to mount the 3/4" EMT fittings. These hold 3" sections of 3/4" EMT conduit that act as the pitch bearings for the box. It's important to get these as tight as you can. They'll take all the force of the stick moving fore and aft. I recommend using a pair of Channel-Lock pliers and a vice to make sure those fittings are as tight as you can make them.

If you're paranoid and have a welder, it couldn't hurt it to weld them in place.

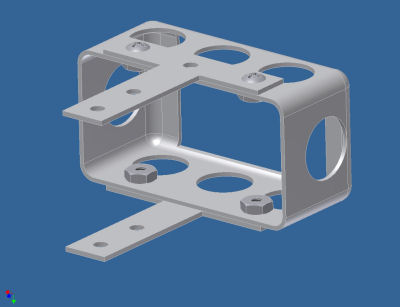

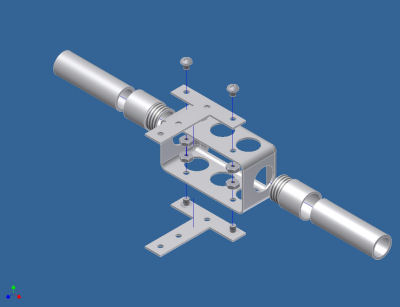

With it all assembled, it should look like this:

I didn't include the nuts that go to the EMT connectors on purpose. They MUST be used. :)

Here's an exploded diagram that shows you how it all goes together:

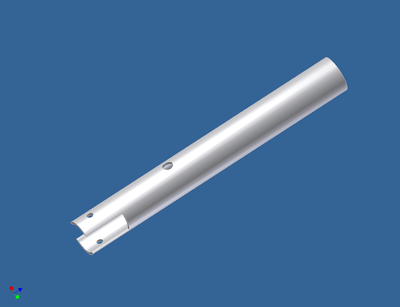

The last part of this assembly is the stick stub. The stick stub is made from a 7" long piece of 3/4" EMT that has had two holes and a notch cut in the bottom. A PDF file of the part drawing is available: media:stick_stub.pdf

The completed stick stub should look like this:

The stick stub is just that - a stub. Your flight grip and lower stick or "stick box" will attach to this using another 3/4" EMT mating connector. The stick stub also provides the mechanical interconnect for the roll and pitch axes.

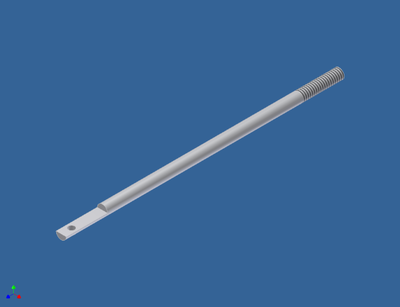

The next part is the roll axis actuator rod. This is just a fancy name for a 6.75" long bit of 1/4" steel rod that you've flatted on one end and threaded on the other. It looks like this:

medial:roll_axis_actuator_rod.pdfHere is a PDF file that shows the details of making the rod. The hole is sized for a #10 screw. When installed, it looks like this:

The screw is not shown. The attachment will take bit of experimenting with to get it centered in the stick stub. You want a #10 screw that's about 1-1/4" long You'll use a "stop-nut" which is basically a regular nut with a nylon ring pressed into the top. The idea is to allow you to tighten the screw down enough to take the slop out, but not enough to bind up the mechanism. Stop-nuts allow this - the nylon ring ensures that they won't loosen over time.

To center the rod in the stick stub, you'll need to get two #10 nylon washers and a few #10 zinc washers. Place the nylon washers on the "outside" of the stack. They'll be the washers that will rub on the inside of the stick stub. The nylon won't produce the noise that a metal washer would when rubbing against the inside wall of the stick stub. Take the metal washers and stack them on either side of the rod until you've got the right number on each side that gives the closest to center fit.

The clevis fork is made by taking a 1/4" extruded aluminum turnbuckle and cutting off the left-hand threaded end. You then drill a hole that's the appropriate size for the bolt you're going to use. In my case the holes were drilled for 1/4" and #10 bolts (not on the same clevis).

Next up, making the wooden bearing blocks for the gimbal... First, you're going to need to download the drawing for the bearing parts.

media:pitch axis bearing drawing.dxf pitch axis bearing drawing.dxf

- This drawing was saved in AutoCAD 2004 DXF format. You shouldn't have any problems reading it using any of the freely available CAD programs, you can download a PDF of the plan media:pitch axis bearing drawing.pdf. The drawing will print full size on a single 11x17 sheet. The blocks are made from 5/8" Birch plywood. However, any good quality 5/8" (or close) plywood will work.

Please take your time cutting out the bearing blocks. Here are some recommendations that should help you get a more accurate result:

- When drilling the three mounting holes in the bearing base, it would be a good idea to drill both parts at the same time to ensure that the holes are placed identically in both parts. The bearings must be square and aligned to one another or the pitch axis bearing shaft will bind.

- When creating the parts with the bearing holes in them, it is far safer and more accurate to drill all the small holes and the two large holesbefore you cut the parts to shape. Trust me, you don't want to be boring a near 1" diameter hole in a part with nearly no material to hang on to while the drill does its job. :)

- The large bearing holes are specified at .95". The easiest way to reach that size is to use a 7/8" Forstner or Spade bit. This will get you to .875" The remainder can be sanded away with a small drum sander in a drill or a drill press. The idea is to get the size of the holes to the point where they're just a little bit loose around the 3/4" EMT conduit that makes up the pitch axis bearing. Make sure that when you're sanding the parts to shape, you do them in assembled pairs.

- If you'd rather not sand the holes to size, you can still get good results by boring a 1" diameter hole instead of a .95" hole. The fit will only be a tiny bit looser than what I've specified and it won't affect how the gimbal operates.

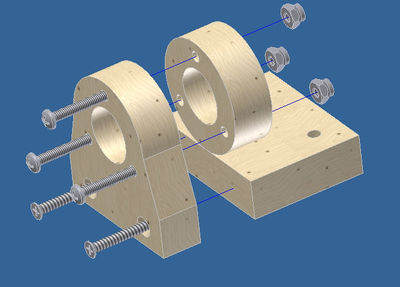

Here is an exploded illustration that shows you how the pitch axis bearings are assembled:

The bearing is assembled using three 1-3/4" #10 pan head screws and three #10 nylon ringed stop-nuts. It's important that you don't use any washers on this because the washers will actually rub on the bearing shaft when it's installed. The base is attached using two 1-1/2" #8 flat head wood screws. You should countersink the holes for them as shown in the model above.

Now that you've got the bearing blocks made, you're going to need to lay out the position of them on the base plate. This spacing will vary, but generally a distance of about 6-1/4" should be sufficient. When you do your bearing block layout, you'll also want to mark out the space needed to allow the gimbal box to protrude up through the cockpit floor. In my version I'm using a hole that's 5-1/2" wide and 5-1/4" high.

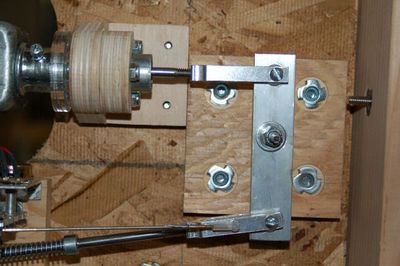

You'll now want to make the pitch axis bearings. They consist of two short lengths of 3/4" EMT conduit cut to a length that will allow them to fully seat in the EMT mating connectors on the gimbal box and extend at least two inches on the pitch actuator side and about 1/2" on the roll axis actuator side. Below are examples that show you roughly how it should look. Pitch axis connection end:

You'll note here how the centering rod for the pitch axis is mounted to the bearing. I'm using a #8 eye bolt that has a locknut on both sides to hold it in place. I chose a #8 because the eye is perfectly sized for a 1/4" bolt. You can also just barely see the Du-Bro ball-link that I'm using to connect the pitch axis to the potentiometer that connects to the computer. The ball-links are very inexpensive and very handy to use. The ones I chose are threaded and have a long enough reach for them to be able to pass through the side of the clevis fork. You can see the nut for the ball on the inside.

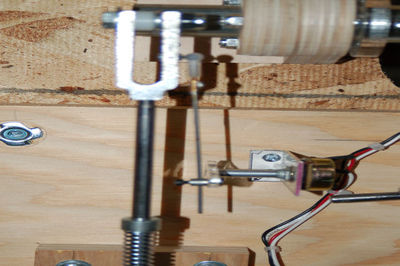

Roll axis connection end:

Here you can see why the roll axis side of the pitch axis bearing needs to be so short. When you move the stick to the far left, the back end of the clevis fork can't come in contact with the bearing tube.

You can also see the roll axis potentiometer connection. Just like on the pitch axis, I'm using a Du-Bro ball-link on the clevis end, and a Du-Bro E/Z Connector on the potentiometer end. This is a very simple and very reliable way to connect your axis pots to your stick gimbal. The last component I'm going to cover is the centering mechanism. The centering mech is very simple. It consists of a 1/4" steel rod that's been threaded on one end, a clevis fork made from a turnbuckle, a pair of springs and some locking collars.

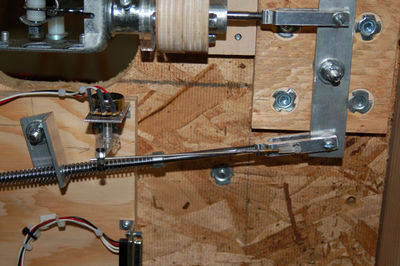

In my design the steel rod is 10" long. Your application may and probably will vary. Here's a picture of the assembly:

As you can see, the whole thing is very simple. A 1x1 L bracket is bolted in place and has a 5/16" hole to allow the rod to pass through it.

A collar on either end holds the spring in place. The springs are compressed against the center bracket just slightly. This provides good centering force for the gimbal.

One option you may want to consider is using two spring pairs. If you stack a lighter spring atop a heavier spring, your gimbal will have light force around the center and it will increase as you move the controls. This happens because small movements around the center only compress the light spring, while movements toward the travel ranges compresses both the light and heavy springs.

That's really all there is to it! Below you'll find various pictures of the assembly that will help out in building your own.