Space Shuttle Tutorial-From Ground to Orbit

| Space Shuttle |

|---|

| Main article |

| Checklists |

| Nominal Operations |

| Nominal Operations Advanced Tutorials |

| Intact Aborts |

| Technical |

| The other space shuttle |

In this tutorial, you will learn in depth how to put on Orbit the Shuttle using real checklists, aiming for an impressive realism. It will bring for T-9mn up to the post insertion actions, roughly 3 hours into the flight, fully configured for Orbital Operations Flying the Shuttle - Orbital Operations

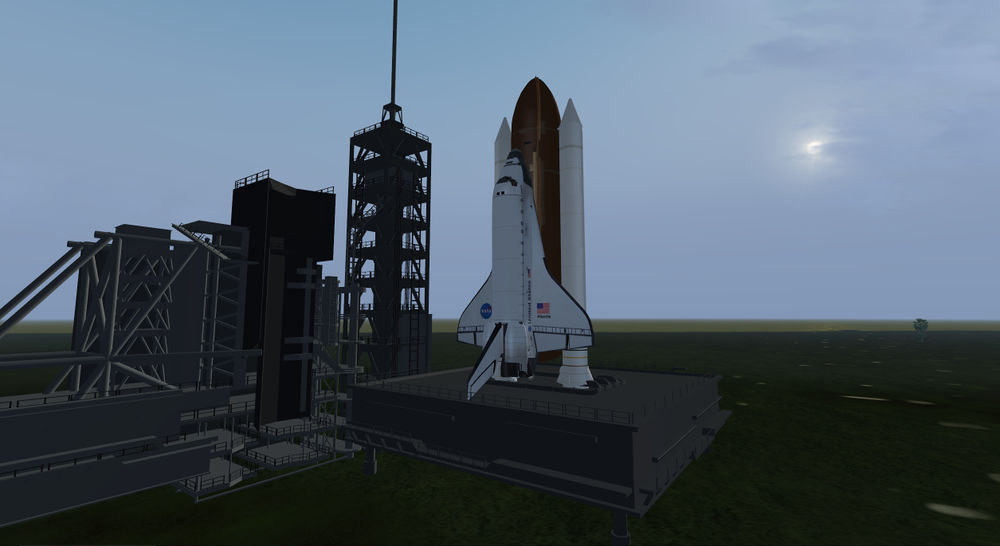

Tutorial was made at Cap kennedy, nice and calm morning.

- Start Flightgear with the commandline options

--aircraft=SpaceShuttle-launch --lat=28.6206 --lon=-80.6133 --heading=90 --timeofday=morning

Heading 90° to have the tail facing the ocean, Shuttle will then perform the famous 180° roll after clearing the Launch tower

Checklists can be found here Understanding_the_Space_Shuttle_Checklist

Prelaunch procedure

Let's start our journey, Astronauts have already been seated in the Shuttle for almost two hours, preliminaries checks are done. Configuration of computers, checks of the pressurisation, and many other tests. We start on the pad, holding the timer at 9 mn before lift off.

Back Up Flight System (BFS) can be activated for those who use dev version of the Shuttle, it allows you to have the CRT 3 displaying the BFS, an independant fifth computer that can track errors and take control of the Shuttle in case of severe malfunctions of the primaries computers (PASS).

We set up the timer at T-9 mn to start the final countdown and start the timer

T-8 mn, Essential Bus are connected to their Fuel Cells, it's a triple redundancy Bus for the critical systems that we can't afford to loose. An example is the Caution and Warning system (C/W). It's vital to always have access to it to know if a failure is happening somewhere.

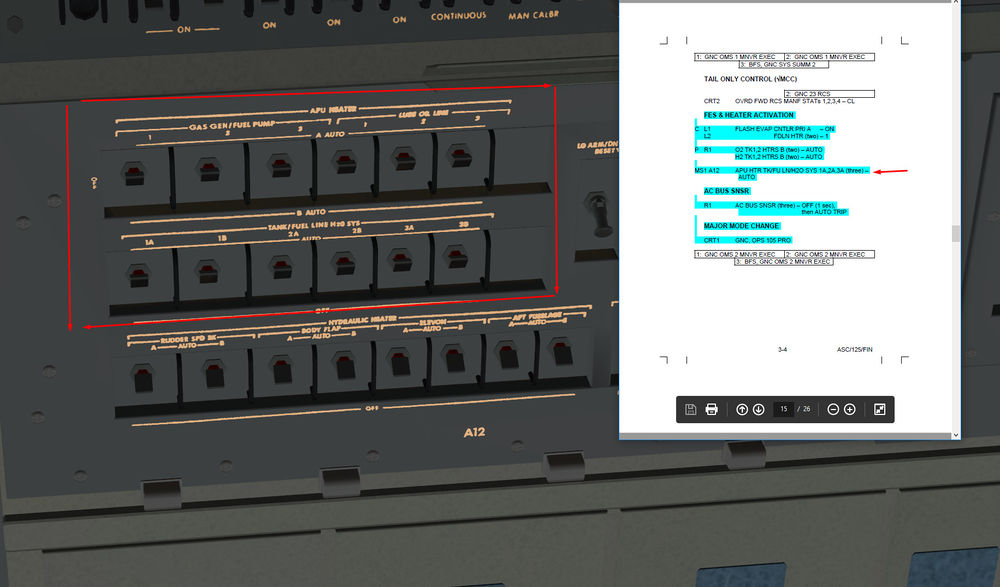

T-6:15 mn, APU are prestarted, Power and Nitrogen(N2) supplies for Water Boiler that will cool oil and hydraulics later in ascent,Electronic Controllers and Fuel tank valves opened for APU, ready to operate.

T-5:00 APU are started, and Hydraulics pumps are bringed to nominal Speed, it is a critical phase, a straight NO GO if something happens there.

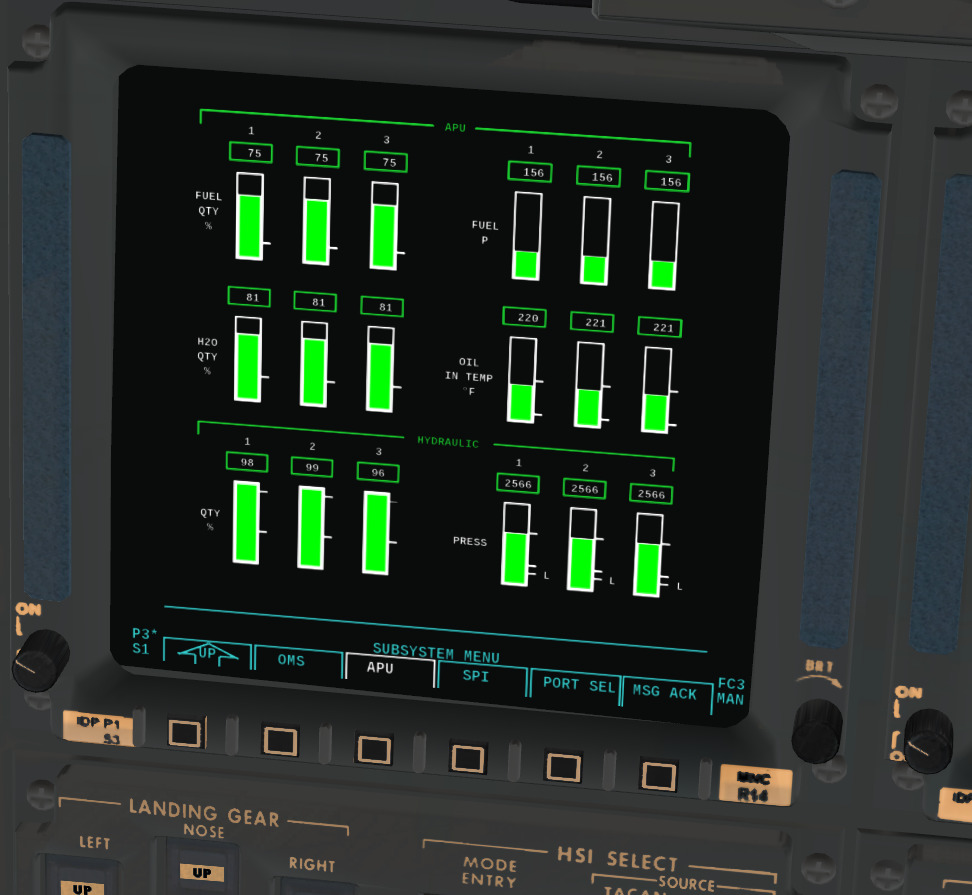

HYD pressure rising to nominal 3000 PSI

The heaters for Water feedline supplying the Flash Evaporator ( FES) are turned off. The FES provide cooling to the Freon ( that cooled most of the Orbiter. Water in the FES boils in contact of hot Freon and is ejected out board by differential pressure, hence it becomes active above 100000 feet.

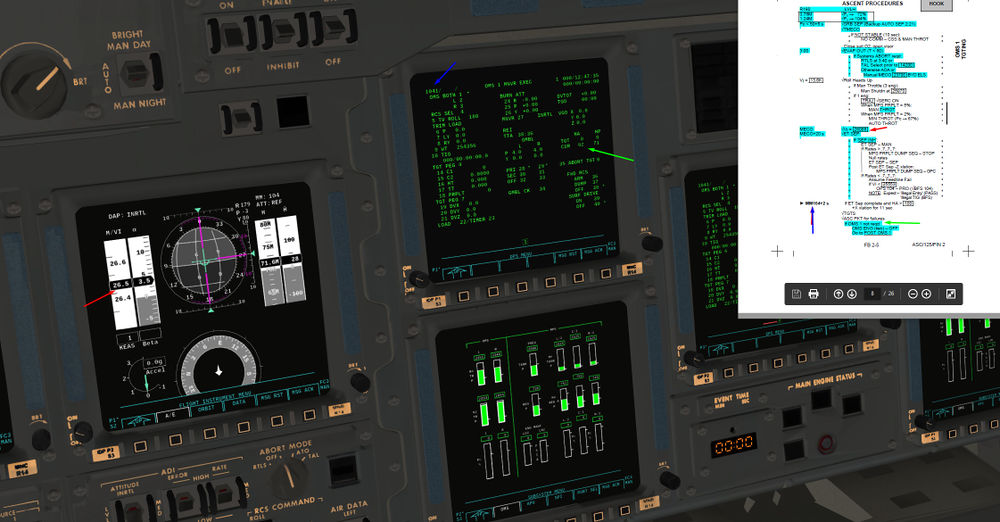

Cross check with in game Checklist, everything looks good

T-7 seconds, we press shift I to turn on the power to the SSME and start a 7 seconds launch sequence, SSME first and SRB's then

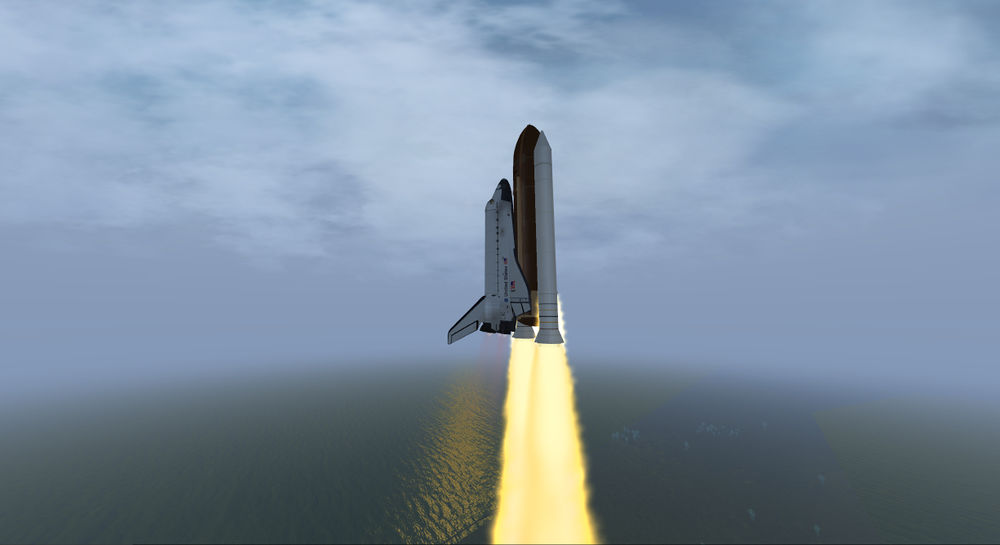

T 0 We have a liftoff and Shuttle rolls after passing the tower

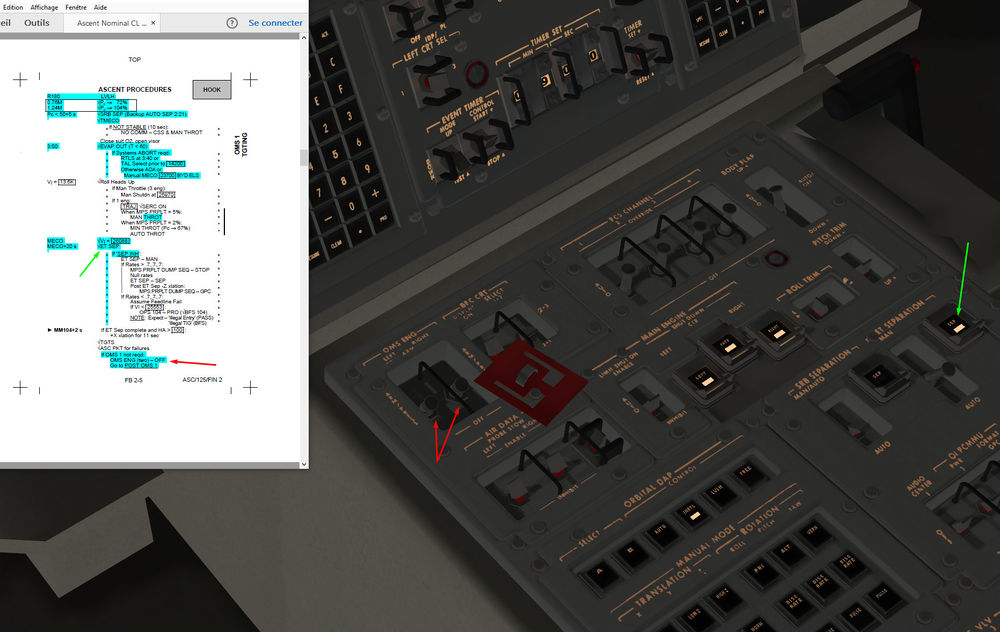

Ascent and MECO

Ascent is a phase fully automatic, which can perfectly be done in manual when you will feel more comfortable. As Flight Gear is a simulation with realistic Flight dynamics, it's important to well monitor the parameters to avoid Over G's or speed, and react accordingly.

First step, the Mach Barrier. Shortly after Lift Off, dynamical pressure will be the highest approaching Mach one.

Approaching Mach 0.7, Thrust is reduced by 30 percent

Then Throttle up again leaving Mach 1.2, dynamical pressure will then decrease ( Higher altitude and lesser density)

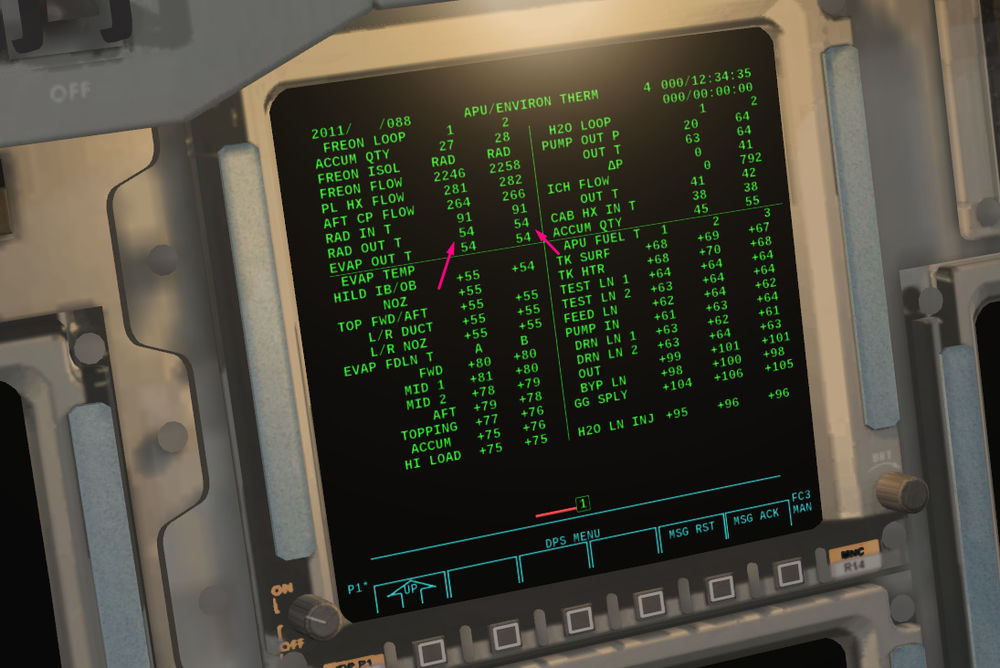

Around 3 mn into the flight, we have to check the Evap Out temperature, which will confirm the good behavior of FES that cool Freon. FES is activated by the GPC after SRB separation. It must be below 60° ideally, but around 70° is fine

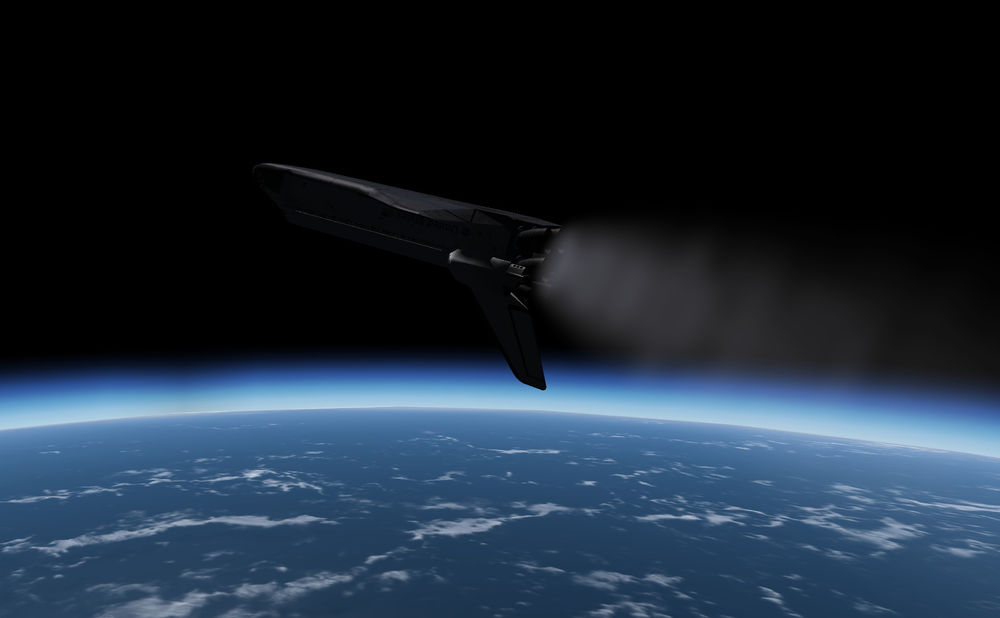

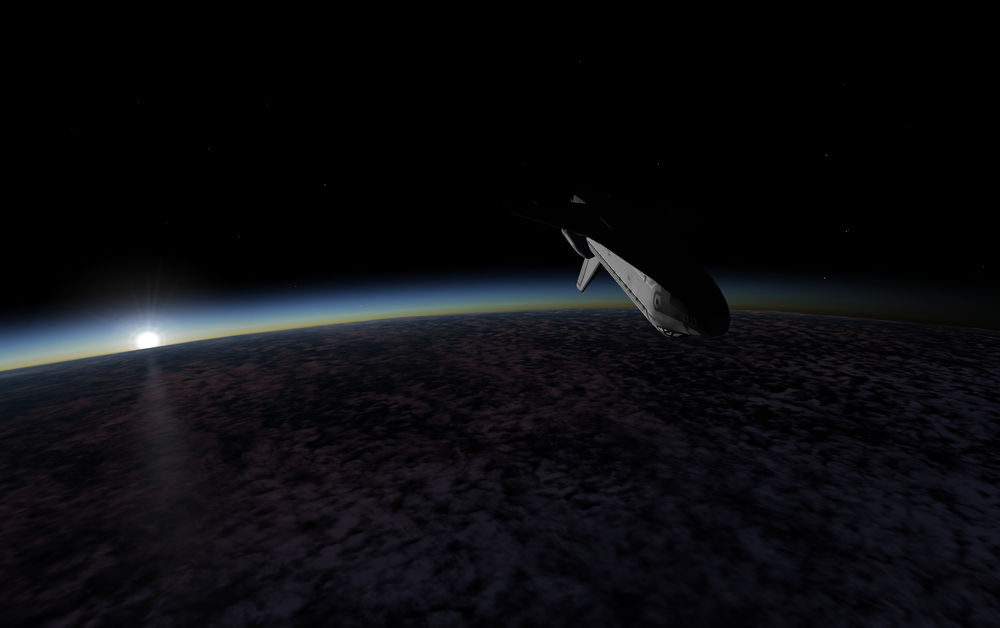

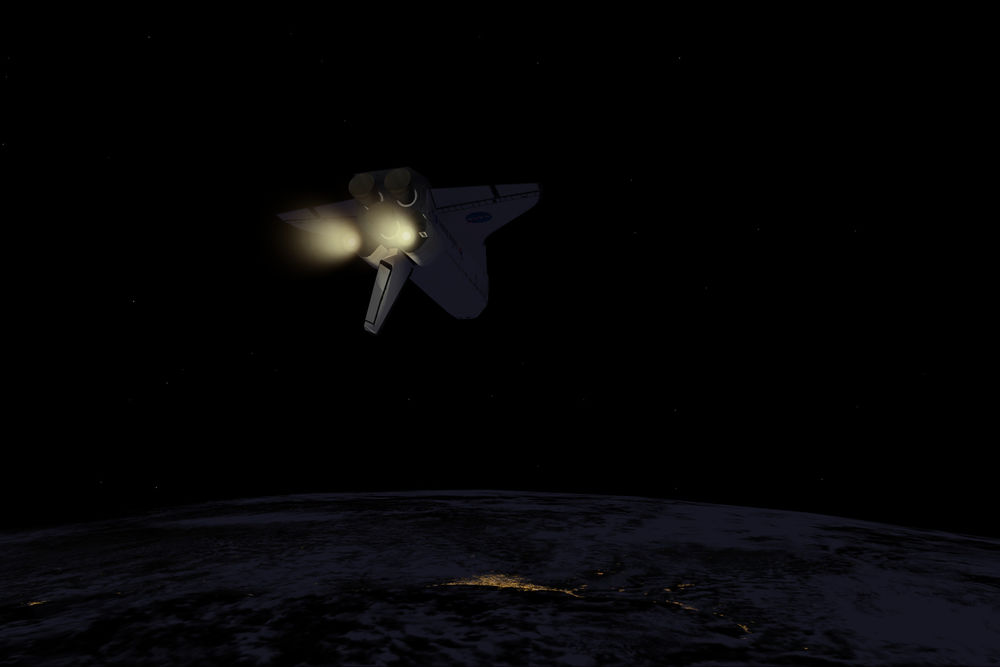

Take the time to appreciate the cockpit view and the outside view with the sun rising above horizon.Terrific

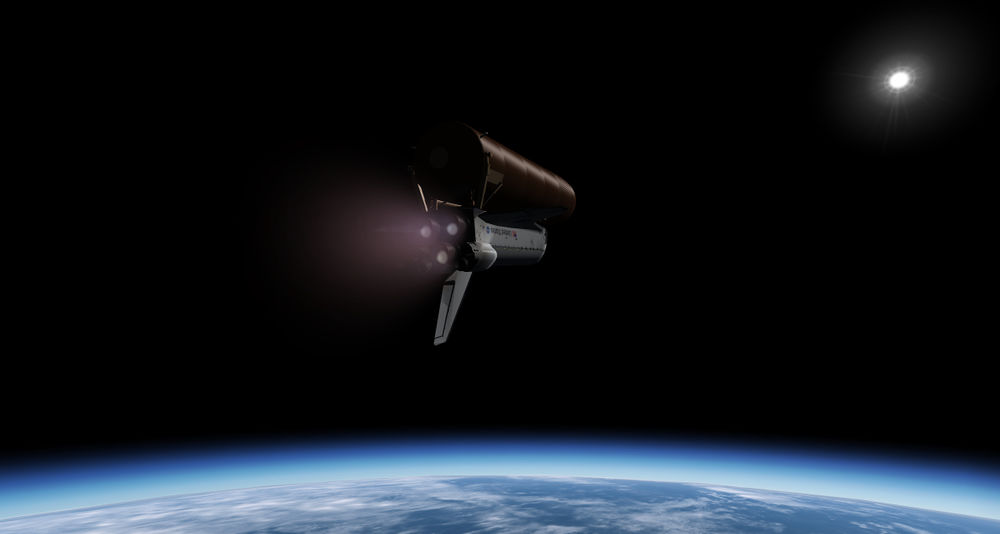

Almost in Orbit, Main Engine Cut Off (MECO) Inertial speed around 26000 fps, in OPS 104 OMS 1 config. However, our obit is 92 Nm by 71 Nm, it's a direct insertion and the apogee is in 40 mn (TTA) We are safely on orbit, no need to raise the perigee, we will not re enter the atmosphere in half an orbit, OMS 1 burn will be skipped

We turn off the ARM/PRESS switch for OMS engines and check that the External tank is well separated. ARM/PRESS switch opens nitrogen valves that allow the opening of injections valves for fuel and oxydizer into the OMS main chamlber. Don't forget to turn them on before OMS burn

Orbital reconfiguration and OMS 2 burn

Normally, if Mission Control Center (MCC) asks we can manoeuver the Shuttle around the ET to take pictures for further Inspection (yellow part in the Checklist) Up to you to do so and take a screen.

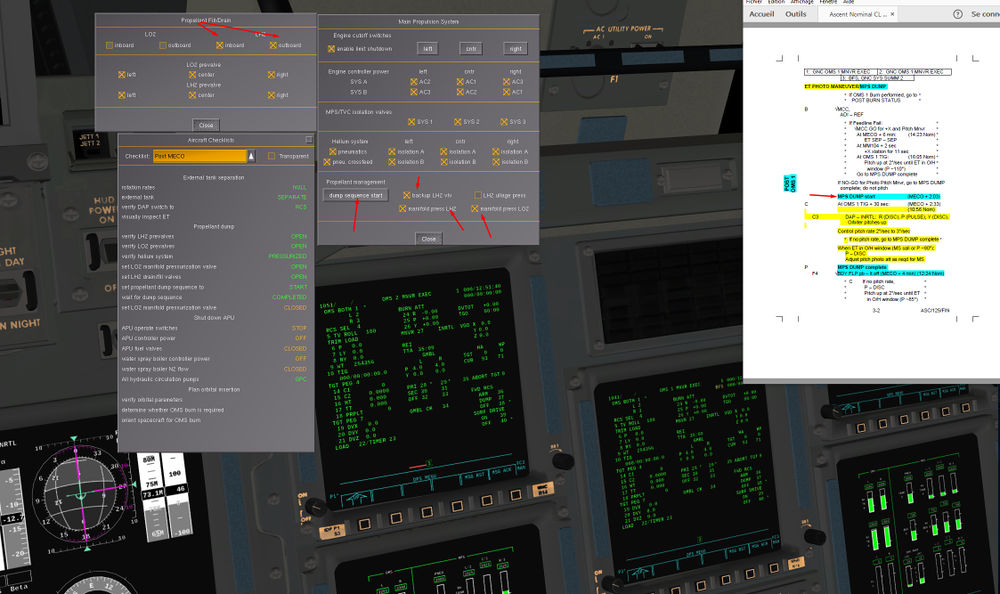

One of the first things to do after ET separation is the propellant dump (Liquid Oxygen and Hydrogen that weight 3 tons in SSME and propellant feedlines) Normally it should start automatically, but we gonna configure it manually. Helium lying in the SSME will be used for that, feedlines fills and drains will be opened and connected to manifold/SSME lines and helium tanks. (Helium is used normally to actionnate pneumatically activated valves in the SSME. Also, it allows some inerting between critical parts in the engines. The Oxygen Turbopump is actionnated by the preburner gases, so there is a risk of mixing between LOX from Turbopump and LH2/LOX preburner mixture. Helium avoid the risk of explosion, a leak in this cavity will lead to an engine stop during ascent)

A nice visual of the dump, LOX going out directly through the main nozzles

Dump finished, the Thrust Vector Control valves allowing SSME hydraulics gimbals are closed

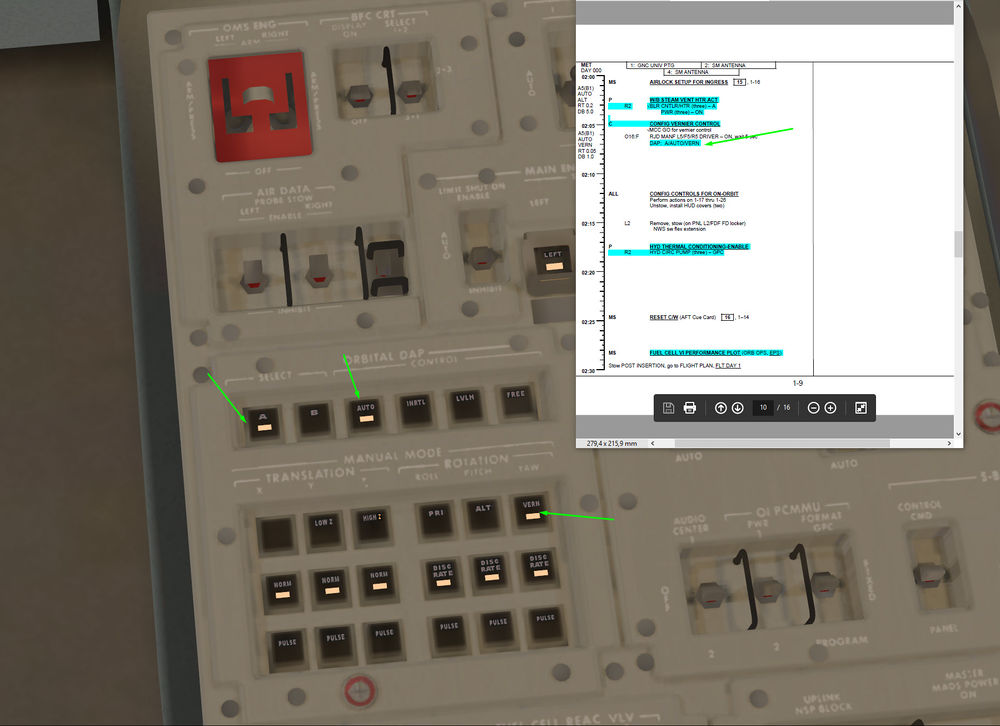

Flights control off and Digital Auto Pilot( DAP) set in Auto

Time now to shutdown APU and HYD It's gonna be a reversed step compared to before, and we will let the HYD PRESS on Normal settings (not LOW)

We can see that the HYD pressure stays at 2600 PSI. It will be kept like that in Orbit by recirculation pumps to allow the liquid to circulate in the orbiter to avoid freezing and pumps cavitation when APU will be started again

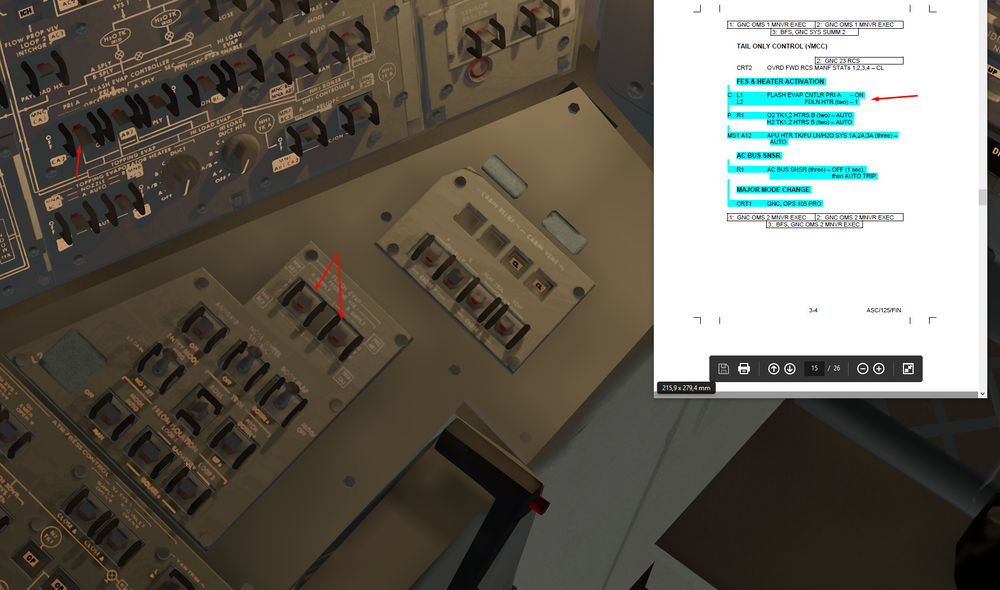

Then, a bit of thermal management. FES feedlines heaters are turned on to avoid water freezing, and FES Primary A is switched to ON ( however, in the sim, it's better to let it in GPC ie. up position, ON seems bugged and freon will not be cooled, except if you are using the last devel version) Effects will be quasi similar, to cool the Freon around 39°F GPC position gives control of the FES system to the computer, that will turn it on and off depending of flight phase and cooling requirements.

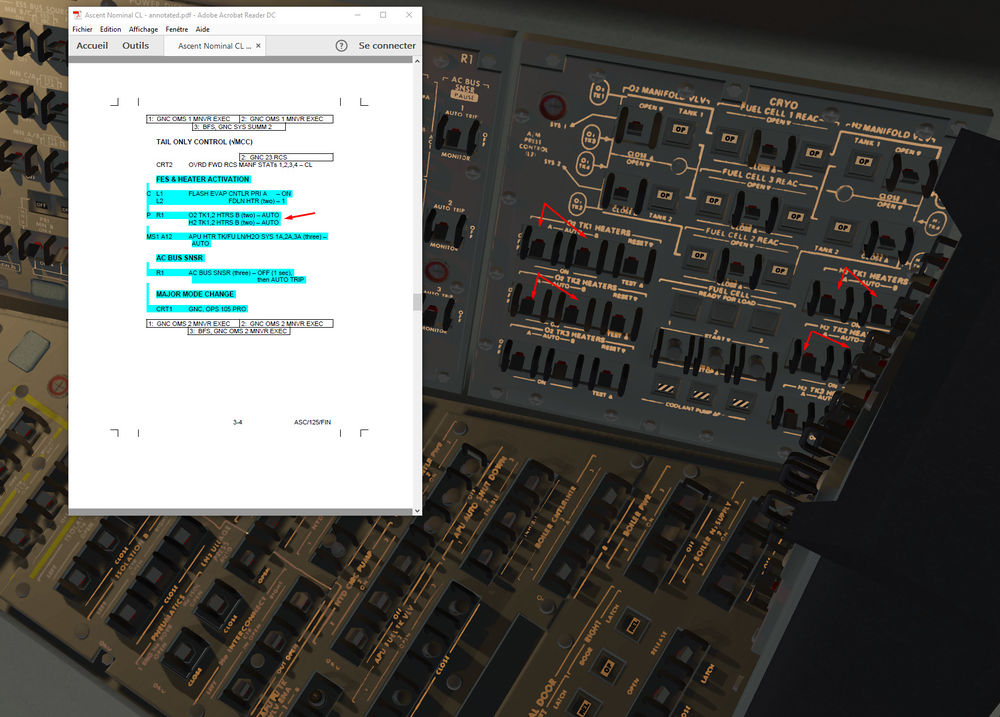

Then we will turn on H2 and O2 heaters for Cryo Tank 1 and 2. When the Cryo tanks quantities ( LH2 and LO2) which feed the Fuel Cells and Pressurisation systems decrease, pressure decreases. Heaters will slightly warm up the tanks to increase the pressure again to its nominal value. For the Oxygen tanks heaters, there is additional controllers to avoid over heating and possible explosion.

On rear Panels, we will turn on the heaters for APU Fuel tank and lines, and for H2O boiler systems. ( A lot of heaters are turned on in orbit, many systems will freeze during long and cold exposure of the space)

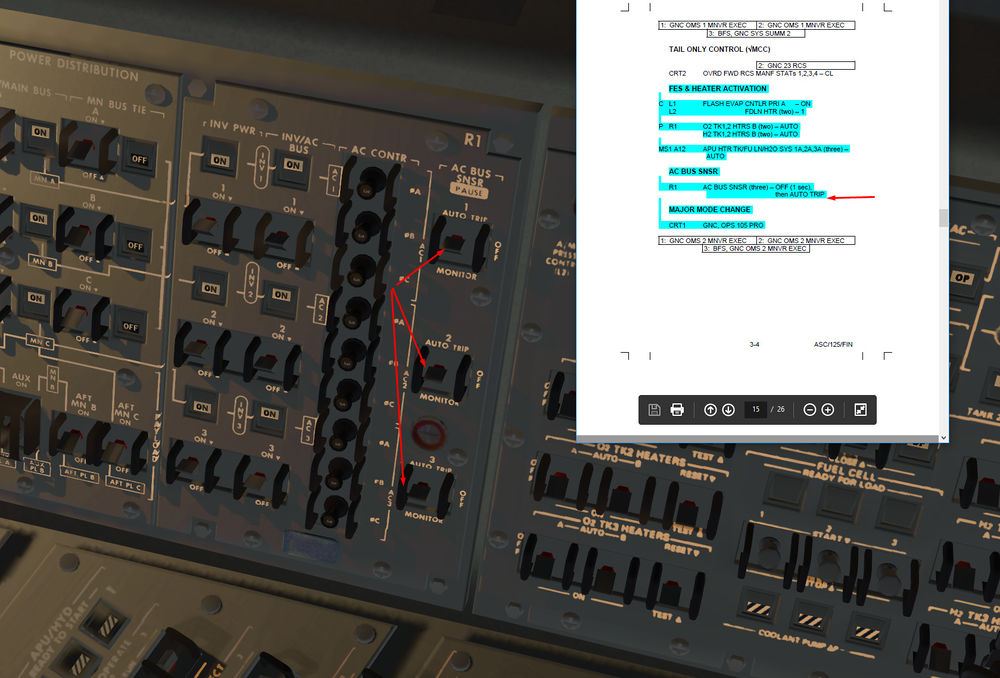

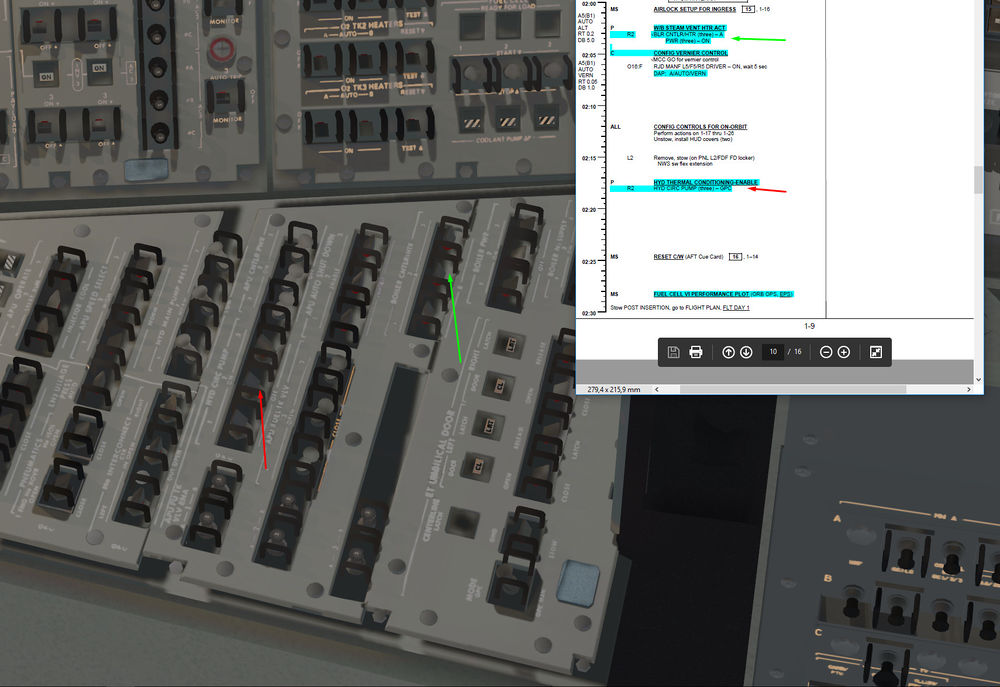

R2 Pilot panel now, AC Bus sensor switches will be put back to Auto trip. In case of AC trouble, it will disconnect automatically the faulty AC Bus to avoid shortage.

It was turned off in ascent to avoid automatic AC bus disconnection in case of trouble, which would have led to engine controllers problems( Loss of two AC busses means loss of one engine.).

Instead, Caution and Warning were still available, and MCC and pilots could assess the gravity of the failure and what would be the next steps.

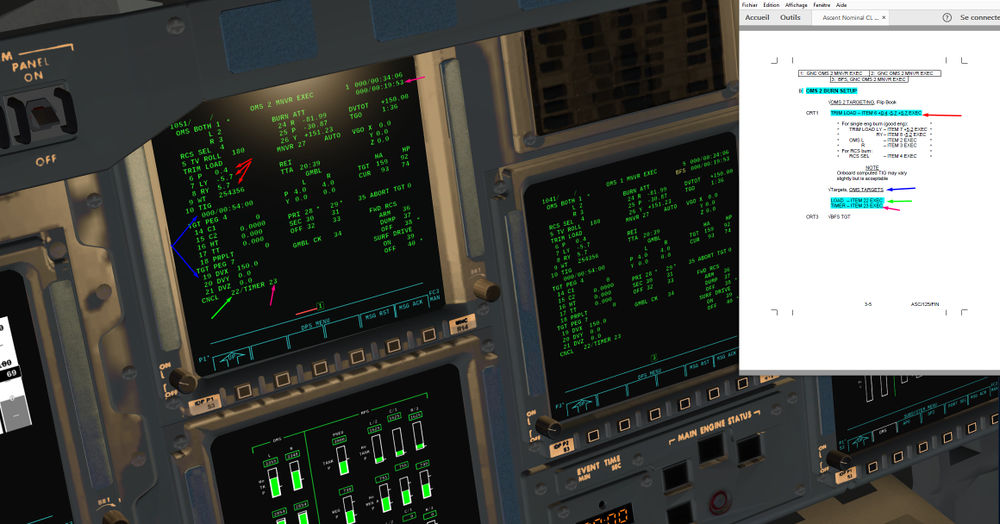

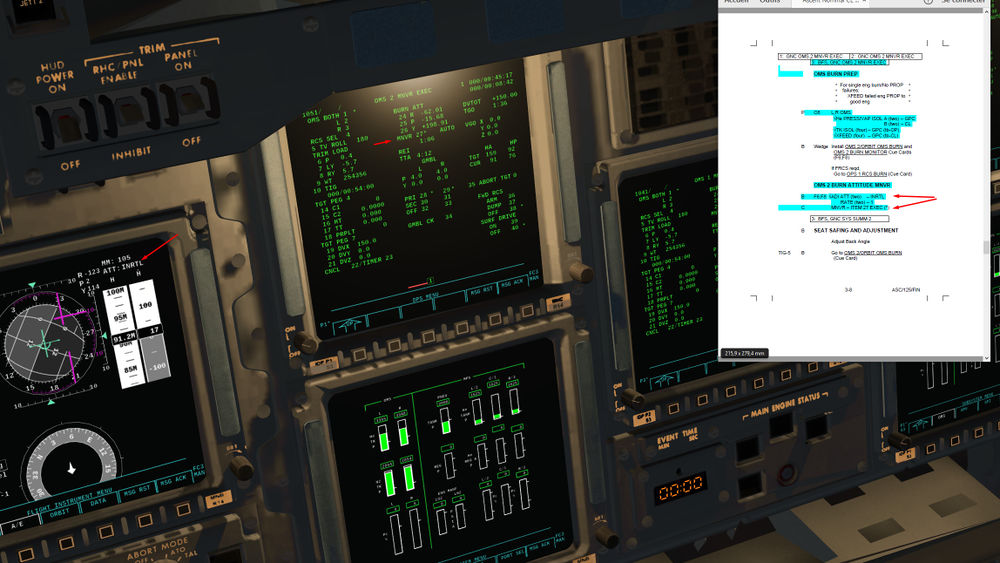

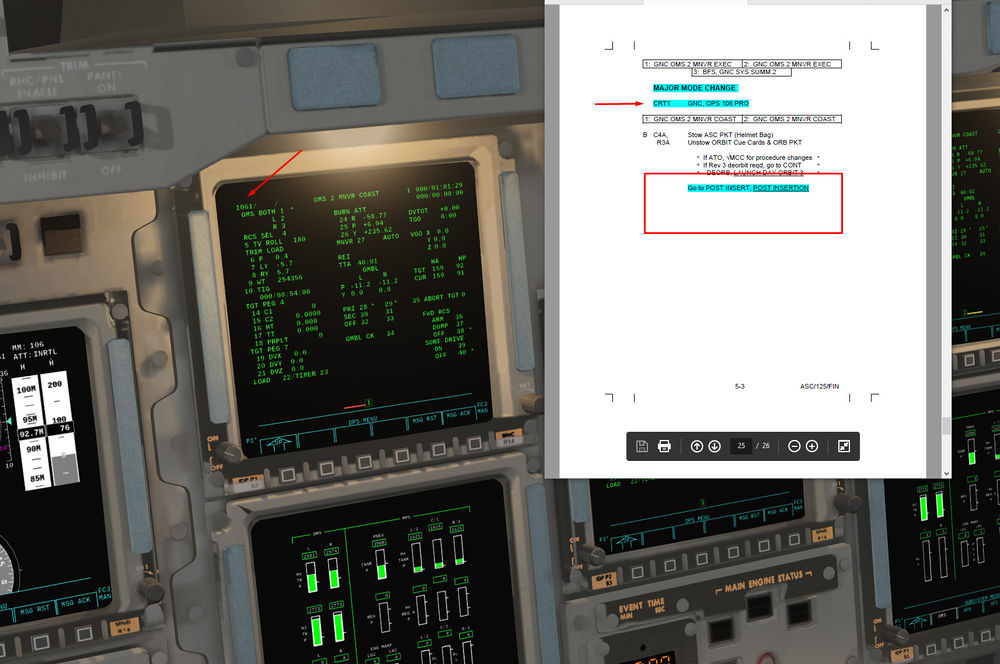

Phew, finally time to change the Operationnal sequence ( OPS) to OPS 105, OMS 2 MNVR

For that, keyboard and OPS 105 PRO

Now, some computer manipulations to prepare the burn. First, we gonna enter some trim angle for the OMS engine, in yaw and pitch. Item 6 to 8 Trim angle (in yaw mainly) allow good gimbals of the OMS. Resultant trust forces will be parallels to the X bodys axis,containing the Center of Gravity (for a 2 engines burn)

Then, we have to decide in item 10 the time of the burn. We gonna do it at next apogee, 20 mn from now (TTA) MET is now 34mn06sec, so we want the ignition to be at 20+34=54 mn into the mission. For that, item+00+00+54+00 EXE

Then, how much thrust will we add? We want to raise the orbit to a new apogee of 150 Nm ( Heads up: 2ft/sec equal in a raise of 1Nm of the orbit height) So we want to raise the orbit by 75 Nm, which corresponds to 150 ft/sec to add in a prograde burn 150 ft/s is then added in item 19, next to DVX ( burn in the velocity vector to change just the height of the orbit, and not the inclination or position of Apogee/perigee) Item 19 + 150 EXE

Forecasted Apogee (TGT HA) is 159 nm, fair enough. You can see that the new Perigee ( TGT HP) is equal to our current apogee (CUR HA) Indeed, we are raising our orbit height, so our burning point ( Old Apogee) will be lower than the new apogee, hence becoming the new perigee.

Loading of the burn solution via item 22 EXE DVTOT appears ( total velocity to gain) and TGO ( duration of burn) Timer started with item 23 EXE

Still 20 mn before the burn, and plenty of things to finish before.

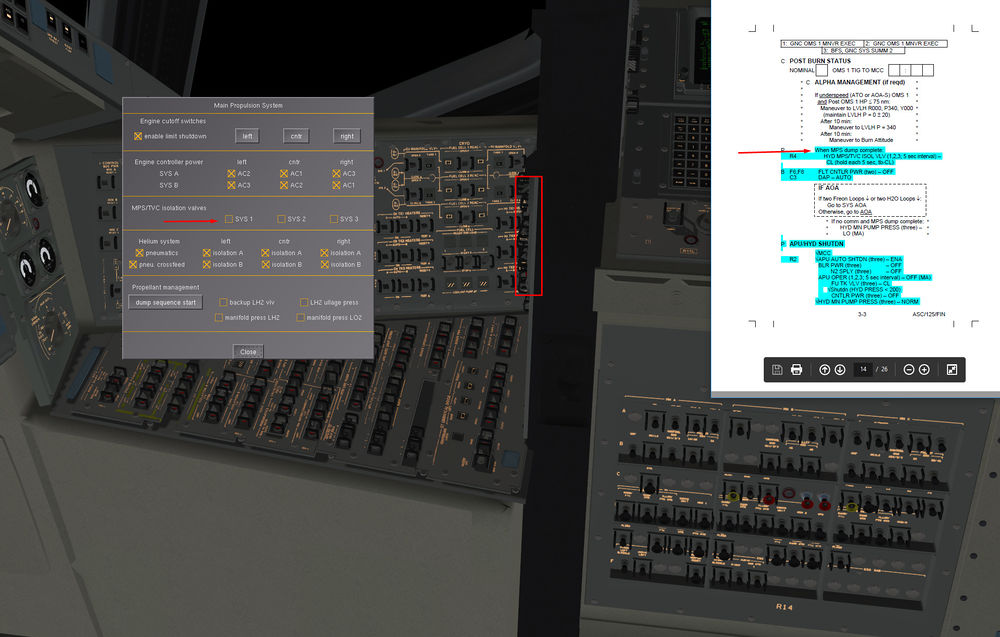

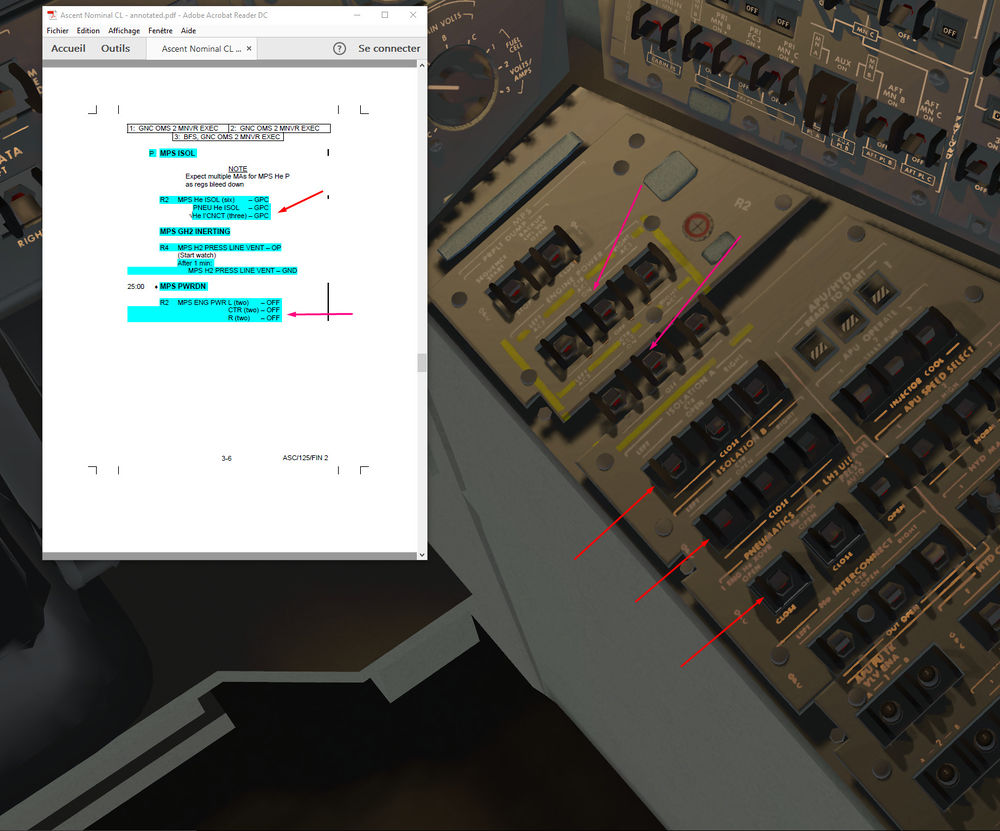

We will close the Helium valves and AC power from Main Propulsion System ( MPS)

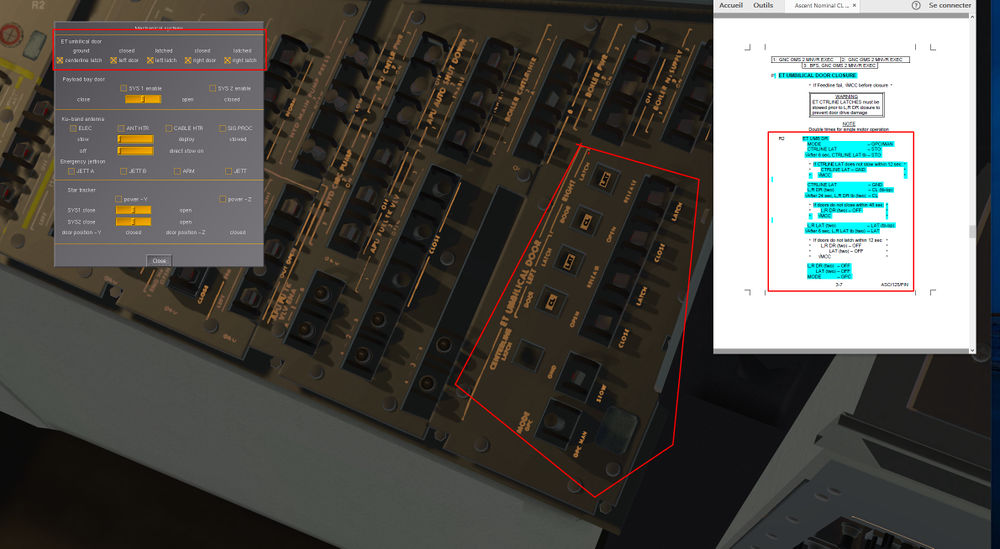

Then, Umbilical doors will be closed and latched to avoid problems during entry.

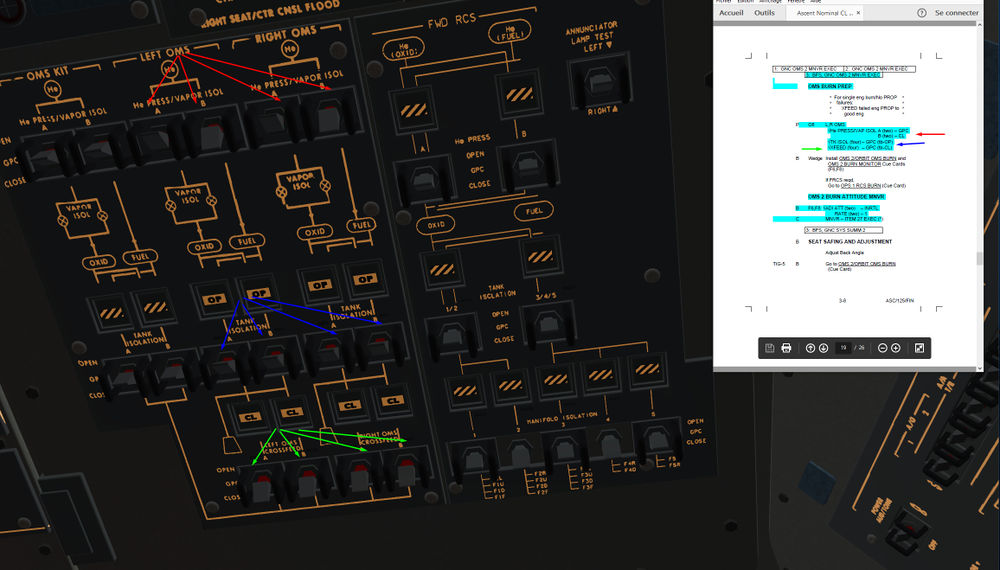

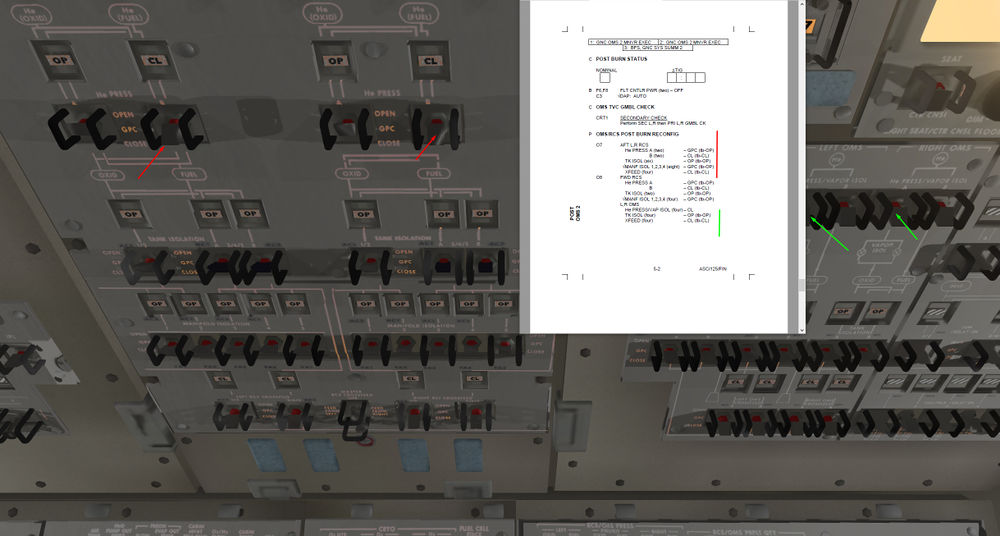

Final preparations for the burn, overhead check that all the correct valves for fuel and oxydizer OMS feedings are in correct position

He Press will allow pressurisation of fuel and oxydizer tanks (closed when no burn is forecasted, to avoid leaks)

Tank isolation will open valves from fuel/oxy tank allowing the liquids to reach OMS inlet chamber. ( A and B valves, for redundance)

We switch to inertial frame on the adi attitude and press item 27 EXE to manoeuver the shuttle to the correct ignition position (BURN ATT in inertial coordinates, hence the necessity to have ADI in Inertial frame mode)

Correct position and sun disappears below horizon

OMS Arm/Press switches are turned on again, and 15 sec before burn, we press EXE on the keypad to confirm the burn sequence

Good visual on the burn, and monitoring of the parameters, 1 mn and 30 sec to go

Burn is over, let's see the results.

New apogee ( CUR) 158 Nm and perigee 91 Nm, almost as planned, perfect so.

We can circularize the orbit at next apogee in 45 mn or not, mission convenience.

RCS and OMS valves reconfiguration after the burn, almost everything is OK, we just close the 4 He Press/VAP valves of the OMS to avoid bad surprise before next burn as stated above ( don't forget to open it again)

Time to move to OPS 106 and to Post Insertion Actions On keyboard, OPS 106 EXE

Post Insertion

We are on our new orbit, waiting for next apogee to circularize the orbit, or not ( at your convenience if you want to try again some OMS burn) Many important steps will come.

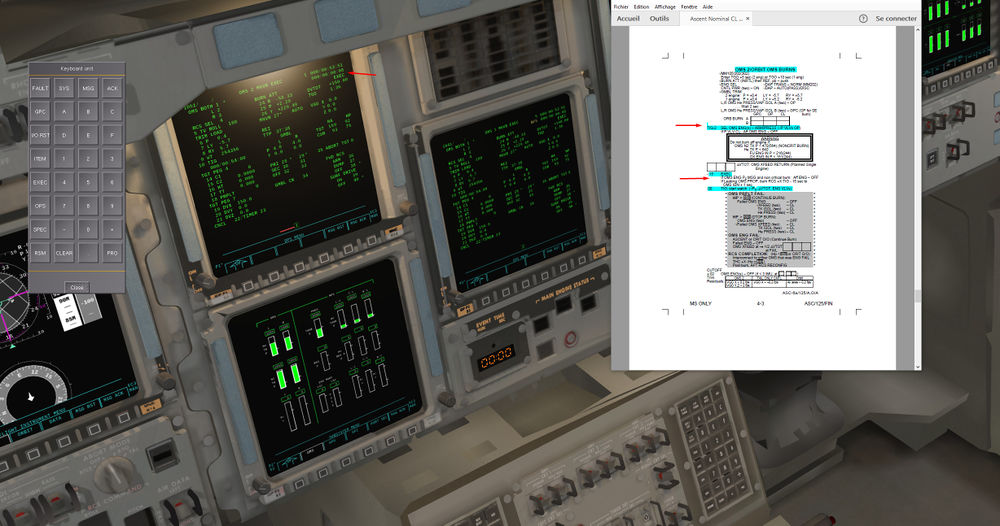

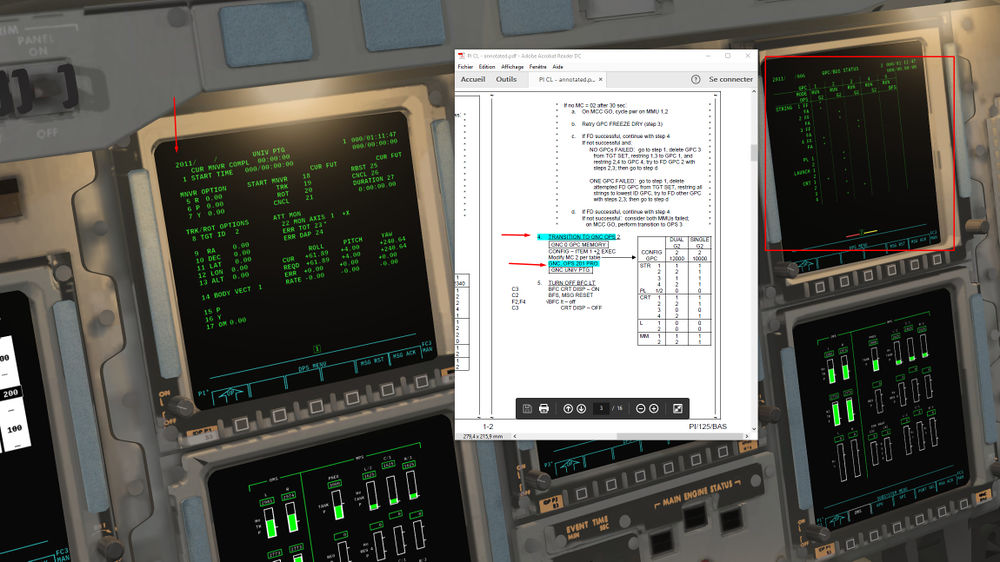

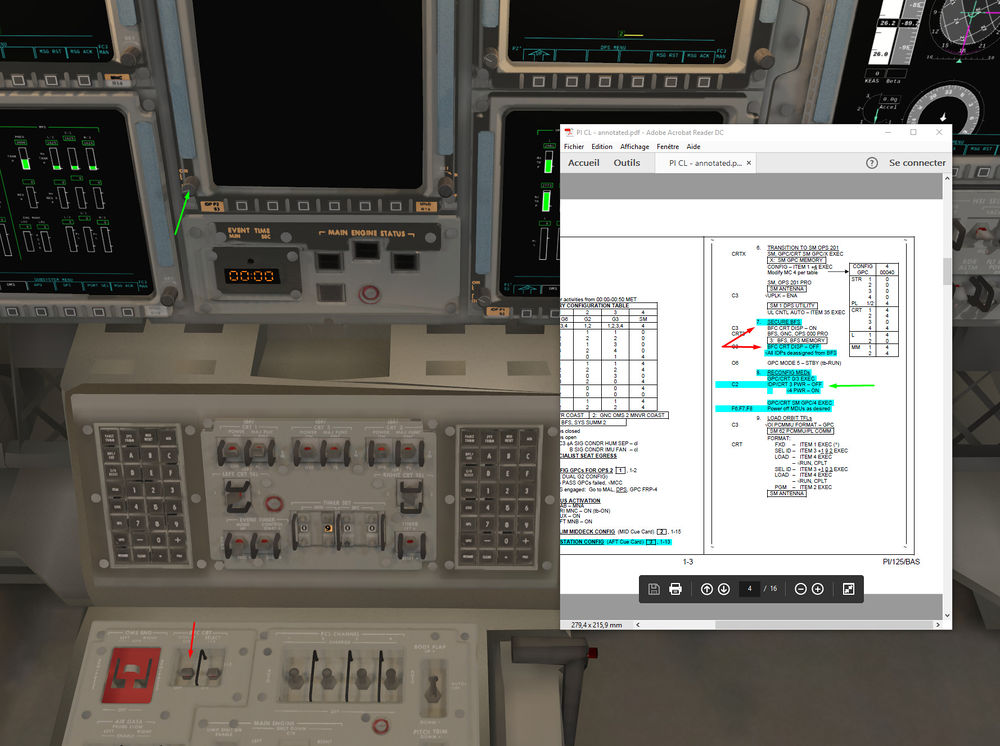

First, we will switch to OPS 2, which corresponds to load Orbit program into the computers.

GPC are not emulated, so no need to go through the long checklist, GPC will be automatically reprogram at OPS 2 transition.

Just for the most curious:

GPC 1 and 2 will contain OPS 2 Guidance, Navigation and Control software (GNC) GPC 3 will be put in Halt mode ( sleep). He will be freeze dried, which means that before going to sleep, a copy of the OPS 2 software will be loaded into the GPC in case of major failure of the others. Very deep level of redundancy here. GPC 4 will receive the System Management ( SM) OPS 2 software and will be switch in Terminate mode ( it will not communicate on Flight Critical buses anymore unlike GPC 1 and 2). GPC 5 that contains BFS software will be put in Halt mode, as no orbit software is contained in Back Up Software and Computer.

So, lets press OPS 2 PRO to load the software, we can see on the right CRT Spec 6 displaying the new configuration of the GPC.

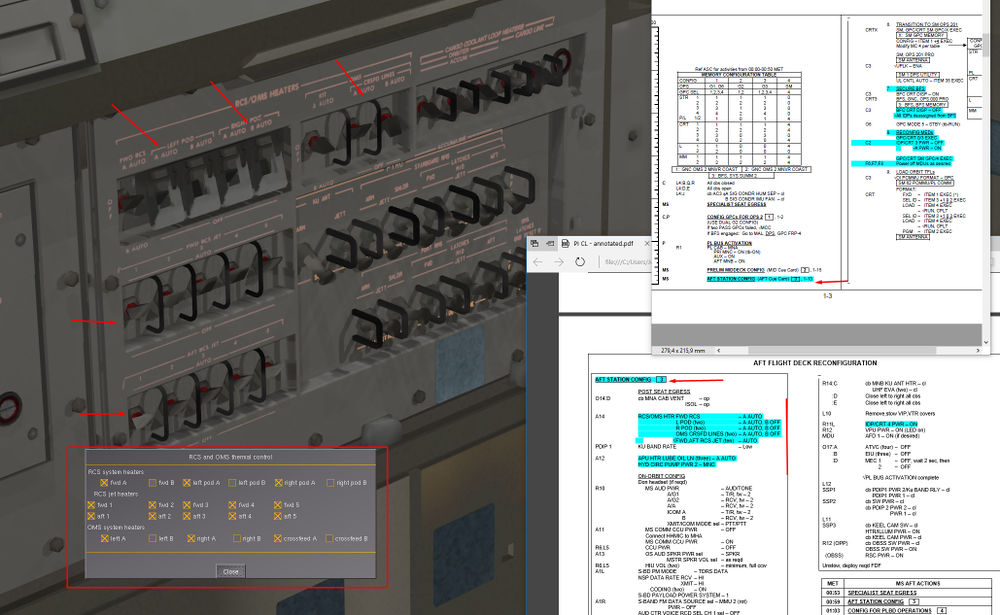

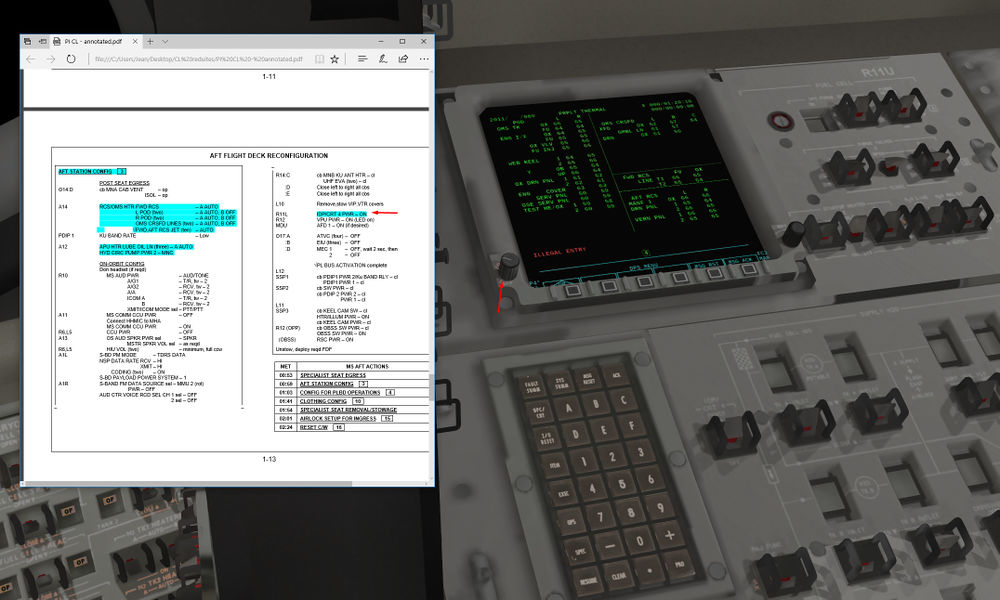

Then again, some Aft Station reconfiguration concerning different heaters ( RCS and OMS related) It's a critical step here. If OMS pods and RCS freeze, we can loose burn and manoeuvring capabilities.

CRT4 on the aft station will be turned on and SM function selected to monitor the Shuttle Systems. You can see on it the Propellant thermal management page( SPEC 89) , all OMS and RCS parts around 60° due to the heaters we just turned on.

Then BFS is secured, which means BFS displays is turned off and CRT 3 ( middle) screen is turned off for power saving

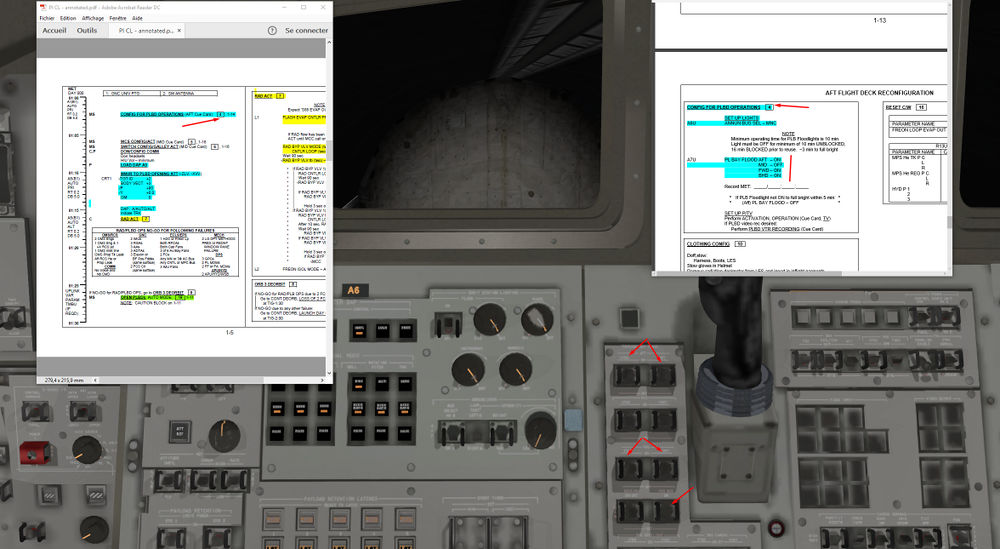

Time to config the payload bay for opening, Lights will be switched on, it takes some time to warm up

Let's manoeuver the orbiter in payload opening attitude.

We want to have the bay (-Z body axes) looking to the Earth and the rear of the shuttle ( -X body axes) to be in the velocity vector.

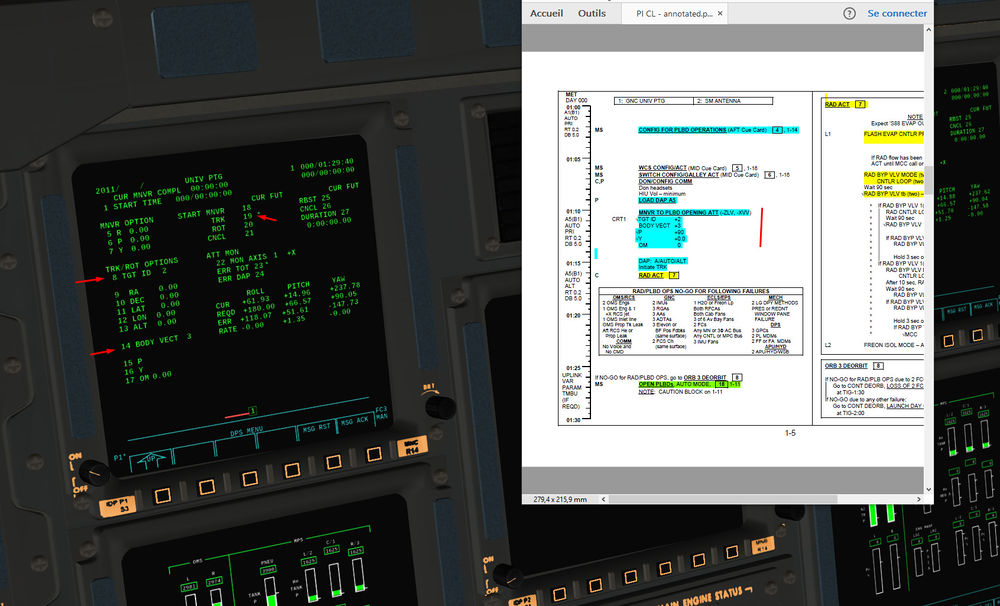

We will use the Universal Pointing software ( OPS 201 EXE in GNC major function)

Item 8 and tgt 2 to specify center of earth as a target, and item 14 and body vector 3 to select - Z body axes as the body point vector. Then item 19 EXE track and DAP auto to move automatically the Shuttle in the correct attitude Bay doors (- Z body axes will point towards the Earth)

We can see that the bay is pointing towards the Earth, and the left wing (-Y body axes towards the velocity vector ( instead of the tail as it should be), small unexpected rotation around the -Z axis, but no biggie. References in game are differently coded, due to frames and orientations natively present in Flight Gear. By using manual DAP ( Free), we can yaw the shuttle by 90° to the right to be in correct position and leave it then in LVLH mode.

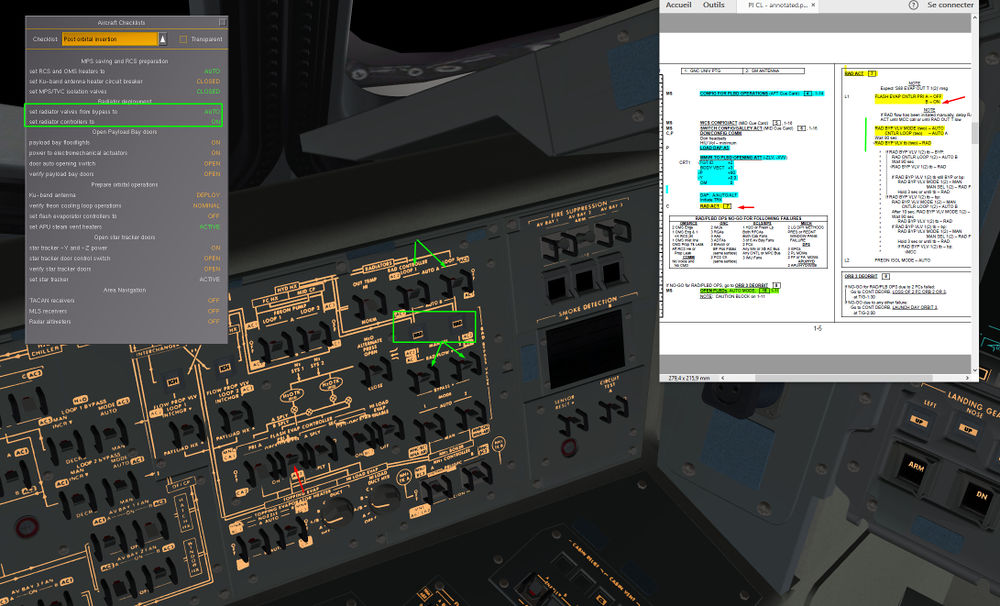

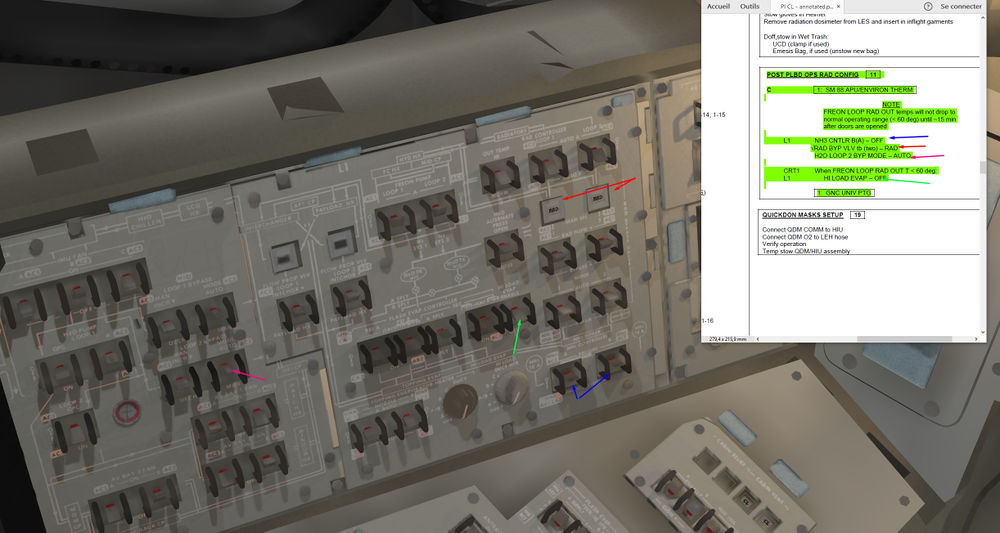

Then we will activate the radiator, that will replace the FES to cool the Freon Loops in space. FES will be eventually used in Orbit Operations if radiators are not cooling enough the Freon, but it's very unlikely.

Flash Evap Primary B is turned on to assist radiator cooling at the beginning. Loop 1 and 2 controllers are switched On, and Radiator Bypass valves are switched to Radiator Flow Some Freon is now going into the Radiator to be cooled down before going back to hot Freon loops and average the temperature. Normally, in real, mode is auto, and it takes 90 sec before Freon goes to radiator at start up. But we will do it manually in the sim, so Bypass valves on Rad Flow.

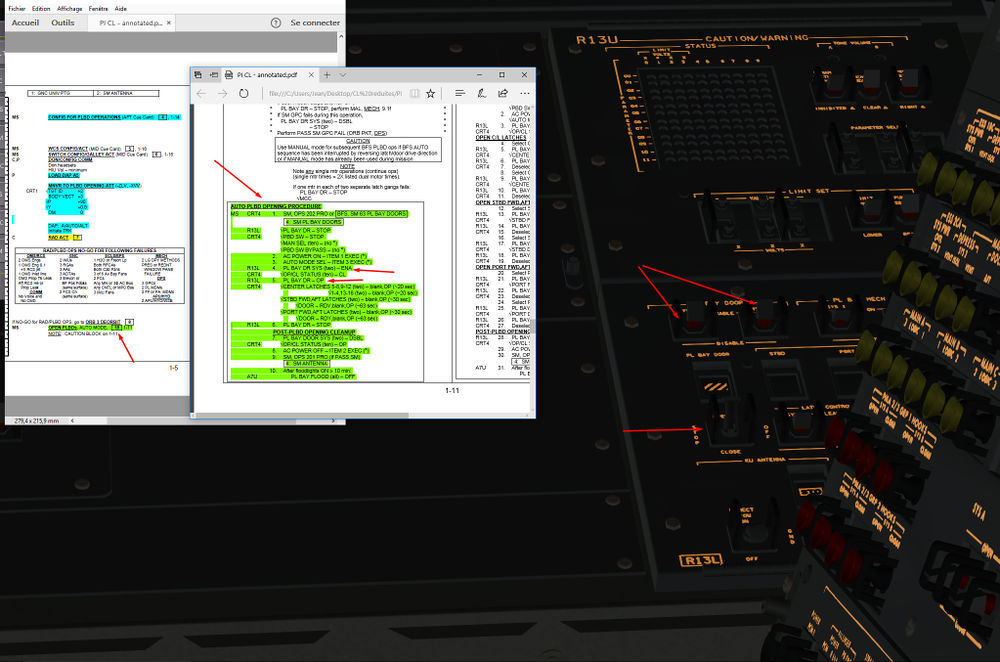

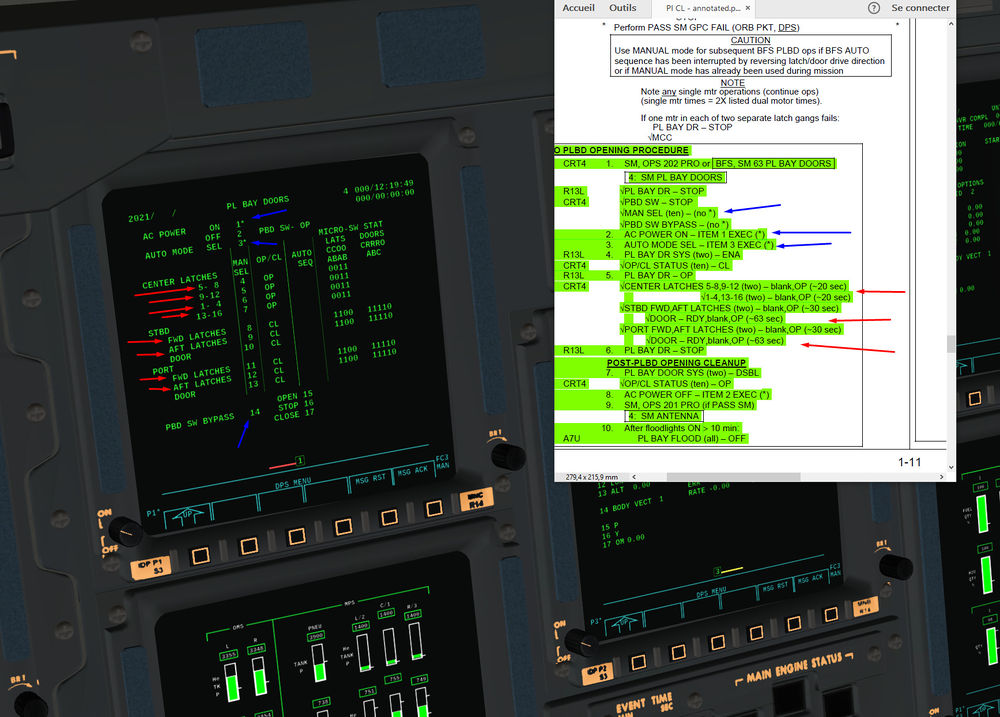

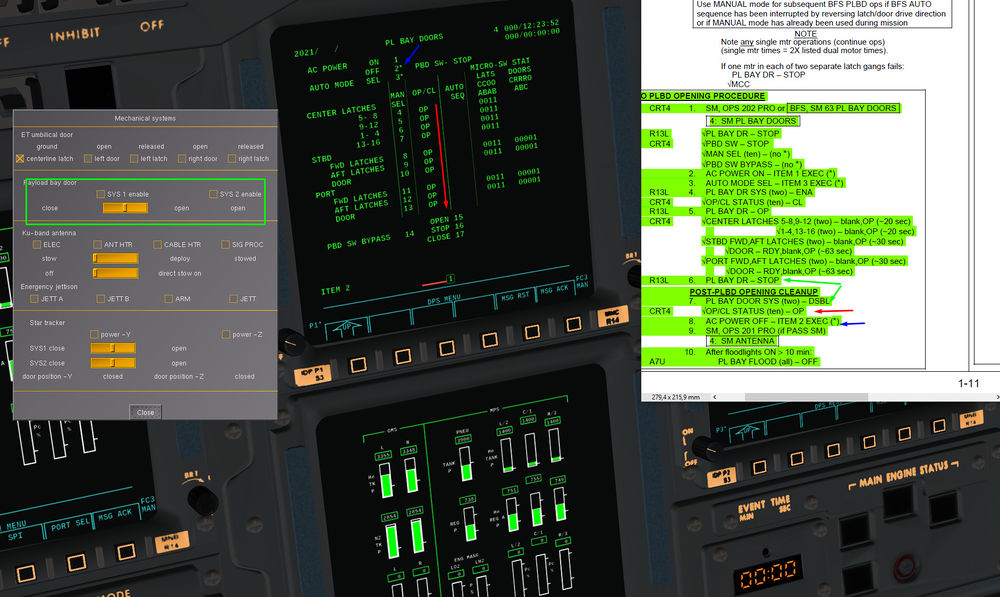

And finally time for Bay doors opening, quite easy in Auto mode, just a couple of switches to play with. You can access and follow bay openings on SM Major Function, OPS 202 EXE Almost all items of the checks are preceding by square root ( remember, it's just a " check that " item, so monitoring on GPC display) You have to monitor that all the latches on Starboard ( and then Port) sides are well opened ( OP) before the door can be opened on the concerned side

Monitoring on the CRT, all latches are opening

And securing the systems after opening ( reversed process we did before)

And the result, nice

Then Ku antenna deployement, some breakers to close to activate power and heating ( I forgot the yellow breaker for signal processing right to the two red Pyro switches)

And Antenna deployment by using the switch on the rear panel

Now that the door is opened, we can finalize the radiator configuration by turning off the High Load evap and the FES, and checking the good behavior of the radiators.

We can monitor on Spec 88 that the Rad out and evap out are below 60 °, thermal management is working well so far.

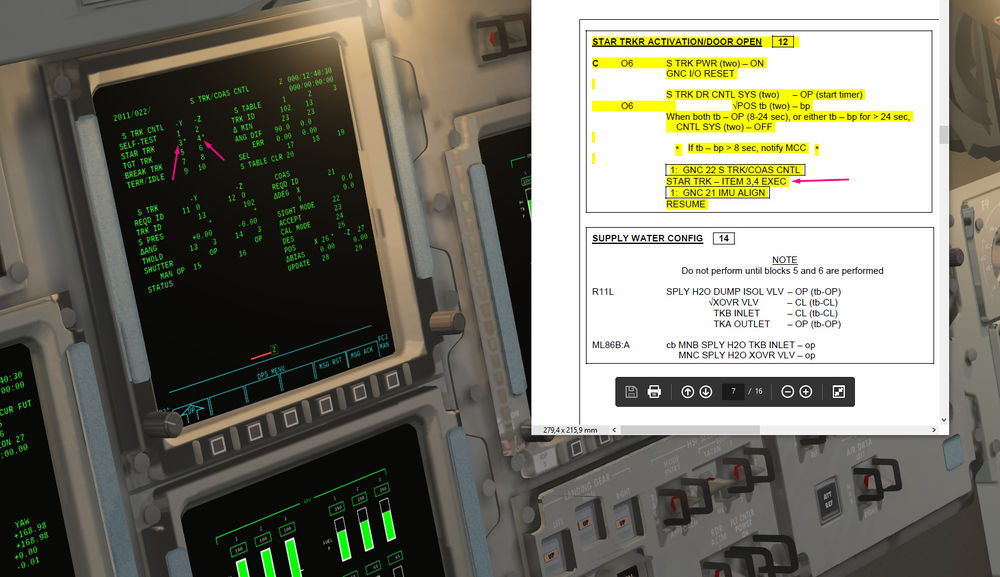

Almost there, time for Star Tracker activation, it will allow us later to align the IMU in respect of Stars whose the inertial position is known by GPC.

Also, ST are used to track an object in orbit ( Satellite, ISS, etc) and allow the shuttle to do some rendez vous and proximity operations ( coupled with very powerful software)

A quick look to the GNC Spec 22, we can have a sum up of the star tracker status, item 3 and 4 allow tracking of " Star of Opportunity" ( Stars that are present in their field of view)

Everything is working well

A few steps remaining, activation of water boilers steam vents heaters.

Recirculations Pumps are also turned on for Hydraulic management in Orbit.

We can check on Spec 87 Hyd thermal page that the pumps are working, they are going to keep the pressure of HYD liquid at 2600 psi in each APU, HYD circuit 1 is being repressurized on the picture below

We configure now the Vernier jets on the DAP. Vernier are 6 small RCS that are use in orbit for attitude adjustement, saving propellant with lower rated thrust RCS Movement is also sluggisher.

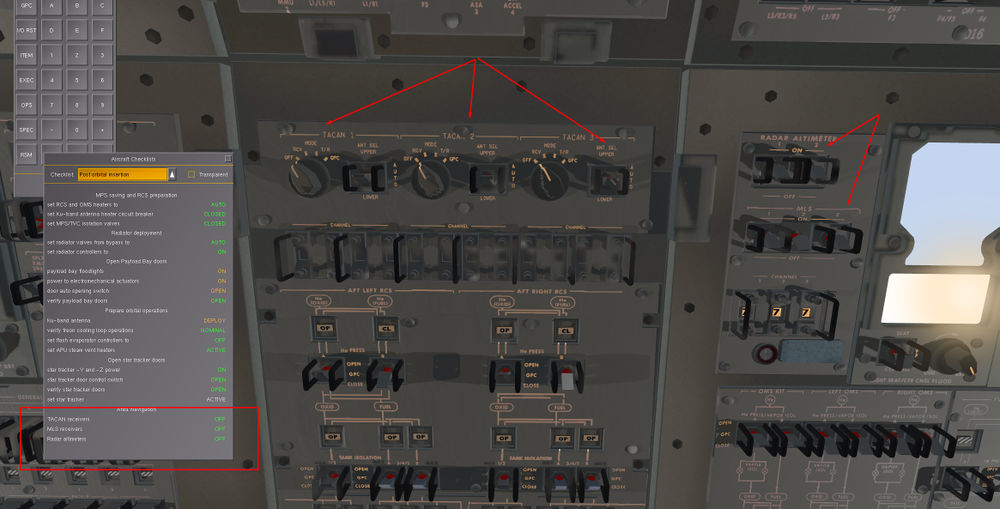

Last step, Turning off Radar Altimeters, MLS and Tacan, no need in Orbit, and power consuming

Everything is ready for orbital operations now. Well done, you deserved a bit of rest.